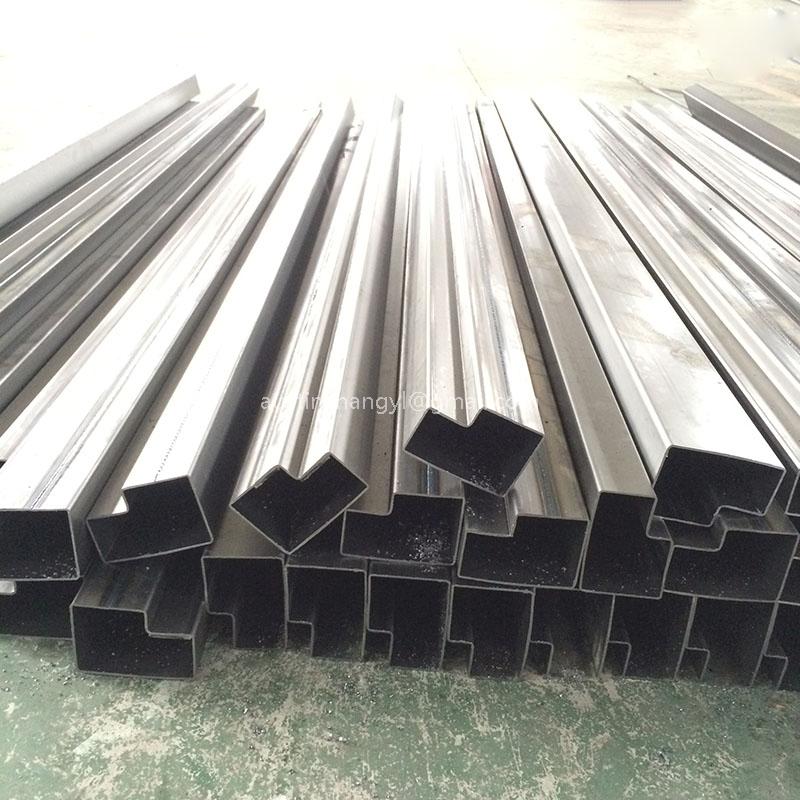

1. Description

1.1 thickness: 1.6-2.2mm

1.2 profiles: per specific profiles

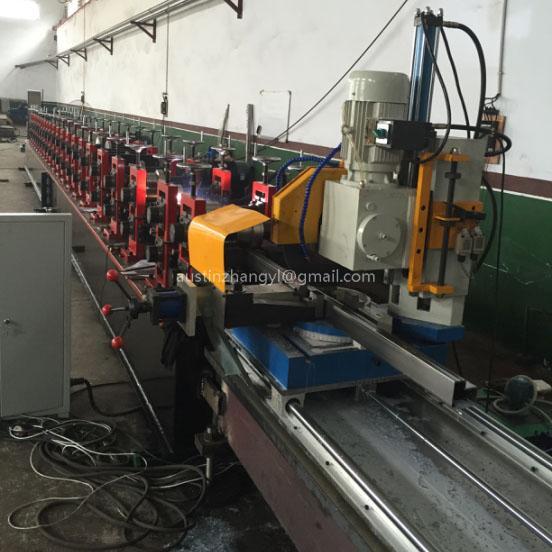

2. Producing Process

Raw material---de coiling---feeding and roll forming---TIG welding---sizing and straightening---cutting to length---product

3. De coiler:

3.1 carrying capacity: 3tons

3.2 inner diameter: 400-550mm

4. Roll Forming Machine

4.1 Feeding rollers: one pair

4.2 Horizontal shaft diameter:φ70mm

Material:40Cr

Rollers: 20 groups

4.3 Vertical shaft diameter:φ80mm

Material: 45# steel

Rollers: 7 sets

Structure: passive rotation

4.4 Forming speed: 2-3m/min

4.5 Transmission: chains

4.6 Main Motor: 15kw

5. Welding Machine

5.1 Argon arc welding machine

5.2 Welding device, welder DC-800-1000

6. Grinding equipments for outside welding line

6.1 Horizontal rollers: 4 sets

6.2 Vertical rollers: 2 sets

7. Water cooling and cleaning

7.1 One set of water cooling device

8. Sizing and straightening Device

8.1 Vertical rollers: 3sets

8.2 Horizontal rollers: 3sets

8.3 Straightening heads: 1sets

9. Fly-saw following cutting

9.1 Cutting mode: computer-controlled following and automatic cutting

9.2 Cutting motor power: 4kw

10. Control system

10.1 Electric control system: PLC